There are numerous issues associated with traditional welding and welding training, from those that are technical in nature to others that revolve around costs and safety.

For example, traditional welding is known to be inefficient and costly, creating a scenario where programs don’t offer the requisite value for money. Traditional welding training is also not constantly adapted or updated to meet the changing needs of the industry, let alone appeal to younger workers or those who are of school-leaving age.

At the same time, traditional welding training is pollutive and highly damaging to the environment. This provides a huge challenge in 2023, where there’s a significant focus on corporate social responsibility and environment, social and governance (ESG) criteria that now informs every aspect of commercialism.

But what do we mean by ESG, and how are Seabery’s augmented training methodologies helping to make the welding industry more sustainable? Let’s find out!

What is ESG?

As I’ve already touched on, ESG stands for environmental, social and governance, which combine to create a framework for company reporting and identify areas in which businesses can become more sustainable.

These criteria capture a broad range of non-financial risks and opportunities that are associated with a business’s day-to-day operations. But what exactly is covered within each distinct environmental, social and governance pillars? Here’s a brief breakdown:

- Environmental: Emissions is a key element of the environmental pillar, particularly greenhouse gasses, air, water and ground pollution. This is highly relevant when discussing traditional welding training processes, with a standard welding machine producing approximately 6 kg of CO2 per hour. Environmental criteria also includes the utilisation of recycled or reusable materials in production processes, and a company’s approach to conservation.

- Social: From a social criteria perspective, companies must also report on how they manage their employee development and labour practices. In the case of augmented welding training, this is known to reduce training time and deliver superior rates of knowledge retention, while also eliminating the health and safety risks associated with traditional welding. Social criteria plays a key role in any business that prioritises ESG.

- Governance: When it comes to governance, this pillar revolves around shareholders’ rights, board diversity and how executives are compensated over time. It also analyses whether dividend payments and executive compensation packages reward sustainable performance, and whether a specific business is free from questionable corporate conduct such as corruption or anti-competitive pricing practices.

How Does Augmented Welding Training Drive ESG?

Seabery’s augmented welding training can impact multiple areas of an ESG framework, particularly environmental and social.

Look at emissions, for example, as augmented trading programs eliminate the production of CO2 and its subsequent release into the atmosphere. Remember, the average standard welding machine produces 6 kg of CO2 per hour, with this based on detailed research that has been carried out in Germany.

The use of Seabery’s augmented training program certainly drives a significant reduction in CO2 emissions, while subsequent savings have accumulated rapidly since 2009. Incredibly, total savings generated during this time are equal to the CO2 emissions that would be generated by a diesel car traveling around the world 29 times!

When it comes to energy consumption, augmented training programs also reduce the amount of electricity used to educate students and impart knowledge.

More specifically, Esslingen University has found that one traditional welding machine consumes the same amount of electricity as 20 of Seabery’s Soldomatic units. In terms of the actual savings driven through the use of Seabery’s augmented solutions since 2009, these are equal to the electricity consumed by lighting the city of Valencia (and its 790,000 inhabitants) for three years or so.

While augmented training does make use of physical equipment and materials, its targeted and more efficient nature also reduces material consumption costs by around 68%. This is seismic, while it also translates into lower laboratory costs for businesses.

But what about social ESG criteria? Well, employee development is central to basic social ESG principles, and there’s no doubt that augmented welding training can deliver more efficient results and 34% more certified welders than traditional methodology.

At the same time, it drives a 56% reduction in learning time, so augmented welding training systems clearly support higher levels of attainment and knowledge retention while also allowing for a higher turnover of students without compromising on results.

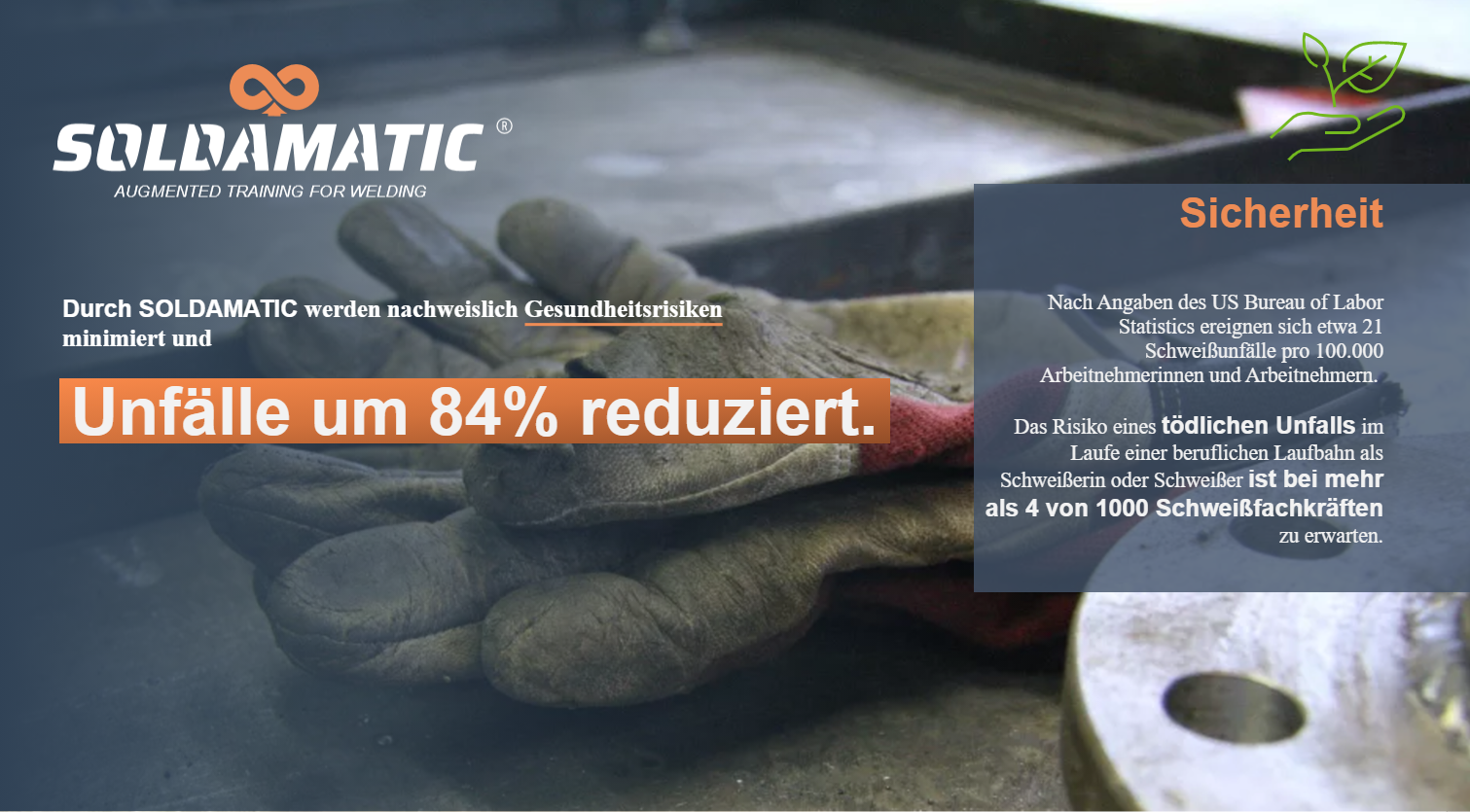

In order for businesses to meet social ESG criteria, they also need to create a safe working and training environment. Seabery’s augmented training technology certainly helps in this regard, as it is proven to minimise risk and reduce accidents by 84%.

According to figures from the US Bureau of Labor Statistics, there are approximately 21 welding accidents per 100,000 workers. The same figures also revealed that more than 560,000 welders report an injury or illness per annum, while the overall risk of fatality is more than four per 1000 over the course of a career.

Make no mistake; augmented welding training solutions virtually eliminate the risk to students, while also helping to teach correct postures and techniques in a completely safe environment.

This can reduce the long-term risk of welding injuries over the course of a generation, particularly Seabery’s technology can also be adapted seamlessly to quickly upskill workers as the industry evolves.