The history of welding is intimately related to the evolution of man and to many of man’s important milestones. Since ancient times, man has sought ways to join materials to create tools, weapons, structures and, ultimately, to improve the tools and objects around him, using the latest technologies. In this article, we will review the entire history of welding, from its primitive beginnings to modern welding techniques, highlighting the key advances that have shaped this discipline over time and ending with the latest technologies applied to work education.

Welding in prehistoric times: Forging and Hammering

Welding has its roots in the dawn of civilization. In the Bronze Age, craftsmen used primitive methods, such as heating metals and using hammers, to join metal parts. Although welding itself as a discipline had not yet taken shape, these early techniques laid the foundation for the future development of metal joining.

One of the earliest forms of welding in history was forging and hammering, more than 3,000 years ago. Blacksmiths heated metal until it became malleable and then joined it by repeated hammering. It is a solid-state technique, meaning that metals are joined in this state by hammering, and not melted (liquid state), as we will see later.

This rudimentary technique allowed the creation of more durable tools and weapons. Forging and hammering were used in the construction of swords, spears and other objects that were essential for the development of ancient civilizations.

Forge welding in ancient times

In the first century A.D., the Romans first developed a gold brazing process, around 60 A.D., recorded by the Roman author Pliny.

Roman soldiers also relied on welding to repair their armor and weapons. These applications were fundamental to maintaining the cohesion of the vast empire and to its economic and social growth.

Another significant event dates back to 310 A.D. when a vast 5-ton iron pillar was built in India by welding, now a world heritage site.

History of welding in the Middle Ages

In the Middle Ages, blacksmiths and craftsmen perfected torch and forge welding techniques. The use of bellows-fed torches allowed greater control over temperature, which would result in stronger and more precise joints. These skills were widely used in the construction of armor and in the creation of ornamental objects that were so common at the time.

One of the most notable applications of welding in the Middle Ages was in the construction of cathedrals and Christian monuments. Blacksmiths began to use advanced welding techniques to assemble the complex iron structures that supported the stained glass windows and vaults of these majestic constructions, although the big change would come with the industrial revolution. At this stage, welding was a basic element in the creation of many of the monuments and symbols of the grandeur of the Middle Ages.

The Industrial Revolution and Arc Welding:

The industrial revolution was a turning point in the history of welding and brought with it the development of new methods and techniques.

One of the most important developments was the use of the electric arc. The electric arc was developed in 1802 by Sir Humphrey Davy, and was first used for welding in 1881 by C.L. Coffin. Electric arc welding was much faster and more efficient than previous welding methods, and quickly became the most widely used welding process.

Another important development in welding during the industrial revolution was the use of oxygen and acetylene. Oxygen and acetylene were discovered in 1802 and 1836, respectively, and were first combined for welding in 1892 by Norman Lockyer. Oxygen and acetylene welding was much hotter than previous welding methods, and was used to weld thicker metals.

Welding processes that were developed during the industrial revolution helped shape the way we manufacture products and build structures. Welding made it possible to build larger, more complex structures and helped reduce production costs. Welding also made it possible to manufacture products that were lighter and stronger, and had a longer service life.

History of welding in the 20th Century

The 20th century saw the development of new welding processes, such as MIG (metal inert gas) welding and TIG (tungsten inert gas) welding. These processes use inert gases to protect the metal from oxygen, resulting in high quality welds and less smoke and toxic gas emissions.

MIG welding became popular in the 1940s and became a common technique in the construction industry and in automotive manufacturing. It uses a continuous wire electrode that is fed automatically through a welding gun. TIG welding, on the other hand, is known for its high precision and is used for welding non-ferrous metals and delicate alloys.

An example of its widespread use is in the construction of large structures, such as bridges and buildings. In 1937, the Golden Gate Bridge in San Francisco was built using electric arc welding.

The use of welding in the aerospace industry also had a major impact on history. Spot welding and laser welding became essential techniques in aircraft and spacecraft manufacturing. These techniques made it possible to join parts with greater precision and less weight, resulting in lighter and more efficient aircraft.

The new era of welding: Soldamatic

Today, welding has entered the digital and automated era. Welding robots are widely used in industry, which has increased efficiency and precision in metal joining. Robotic arms programmed to weld accurately and quickly have revolutionized manufacturing in many industries, including automotive and electronics.

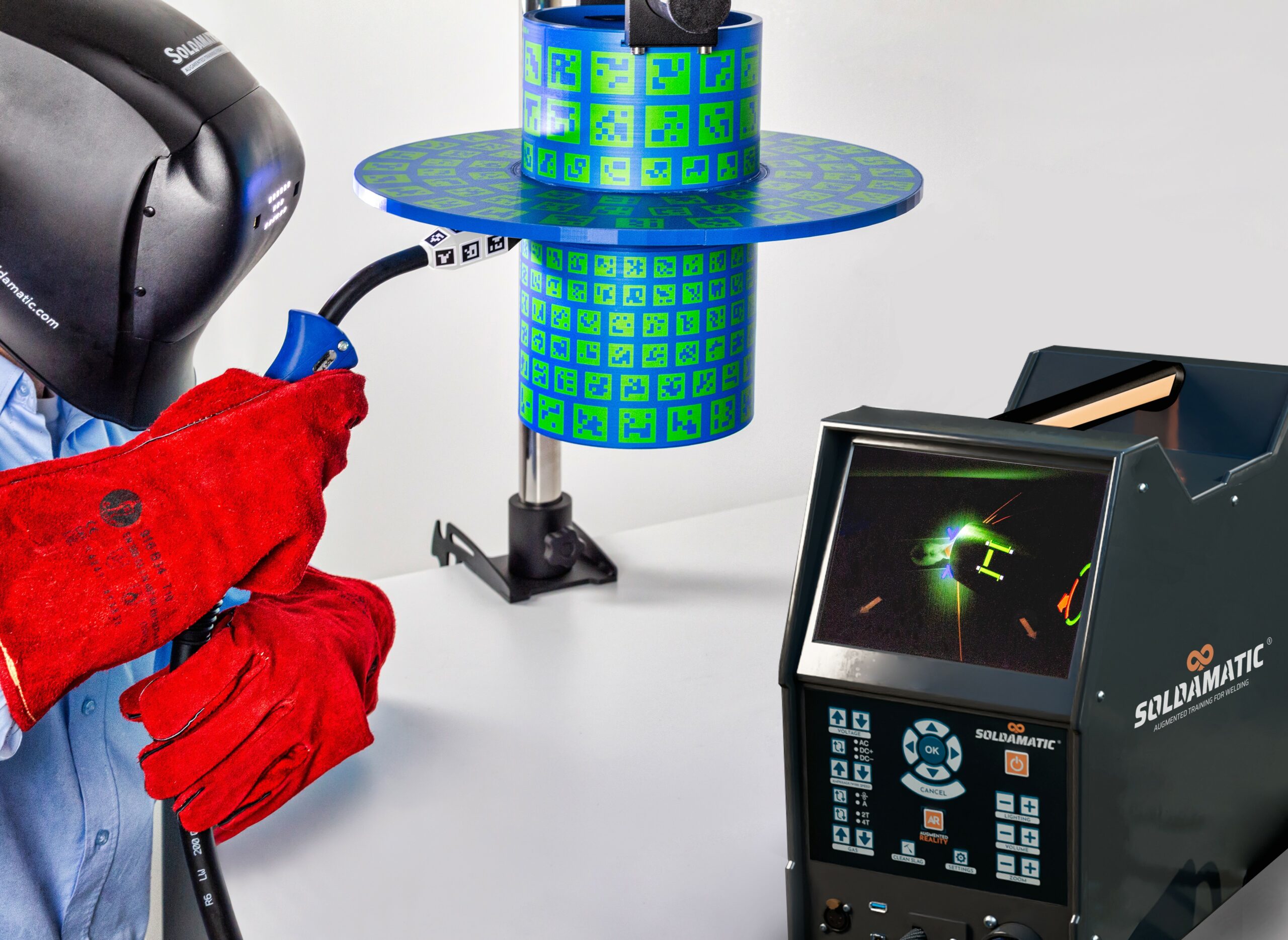

New technologies have even reached education. Now, learning welding processes is more efficient, sustainable and economical thanks to welding simulators such as Soldamatic.

Soldamatic was the first welding simulator based on augmented reality and developed by Seabery. This simulator is at the forefront, pioneer in the market and present in more than 80 countries. It has become an essential tool in training centers around the world for both manual welding and robotic welding.

Conclusions

The history of welding is a testament to human ingenuity and the evolution of different civilizations. From its modest beginnings in ancient times to the state-of-the-art welding techniques of the modern era, this discipline has played a crucial role in building the world as we know it today.

We have reviewed from primitive forging and hammering methods to the discovery of the electric arc during the Industrial Revolution. We see how welding has evolved to encompass a broad spectrum of applications and markets including the automotive, shipping, railroad, oil and gas, and aerospace industries.

Welding has evolved into the digital age with faster, safer and more accurate models, including the way of training in this art, thanks to Soldamatic. Who would have thought that welding can now be done using augmented reality? The future of welding is unpredictable.