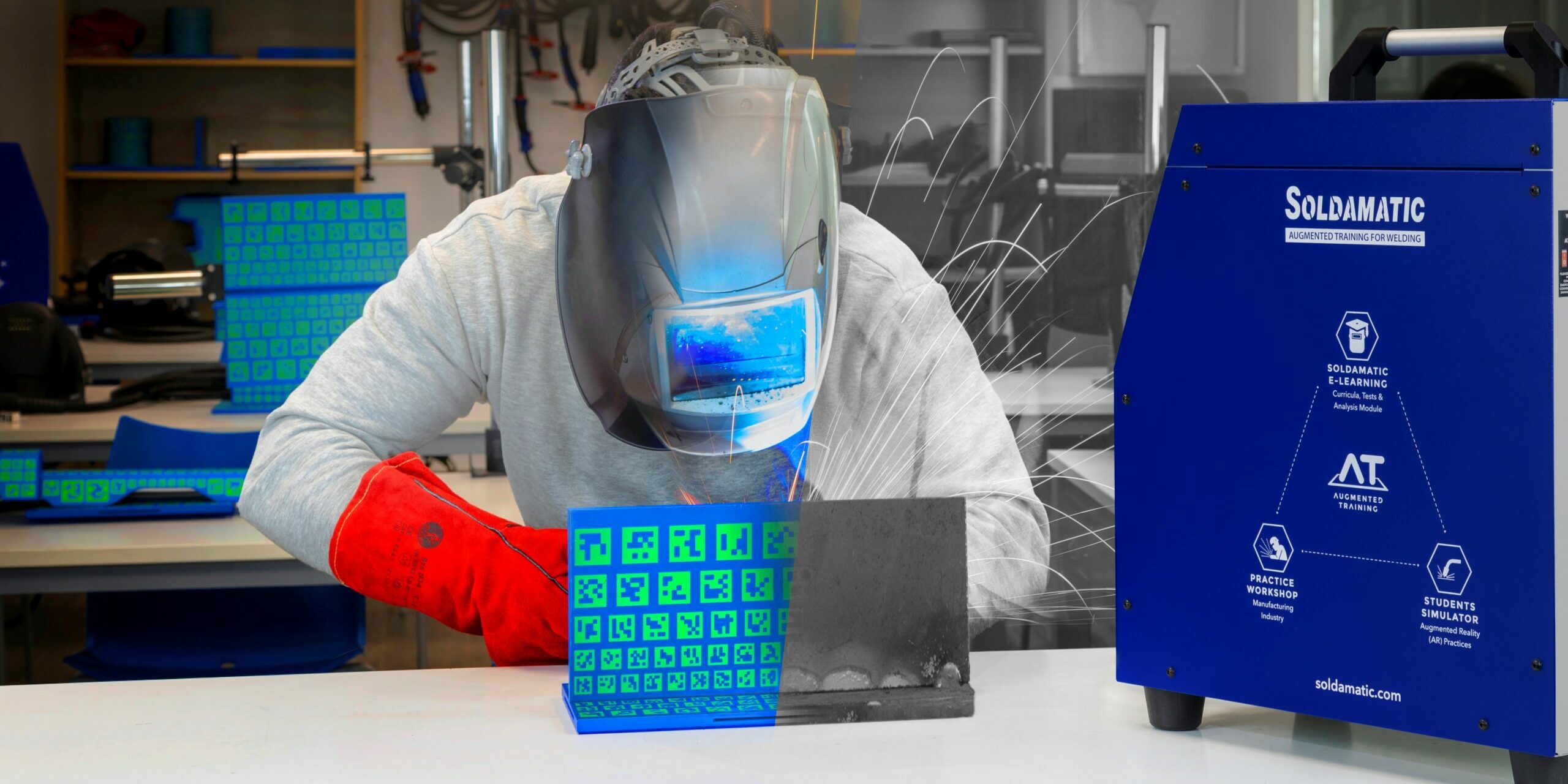

Soldamatic’s patented and market leading training solution is the first of its type to leverage augmented reality, enabling users to learn welding safely while benefiting from higher levels of knowledge retention.

At the heart of this training solution is HyperReal-Sim™, which is an exclusive and cutting-edge feature that delivers the most realistic training experience outside of corporeal welding.

But what does our HyperReal-Sim™ offer trainers and students from a practical perspective, and what are its unique benefits in the marketplace? Here’s a much closer look at the innovation:

OK, So What is HyperReal-Sim™?

In layman’s terms, HyperReal-Sim™ leverages both technological and corporeal elements to create an authentic and multisensory training experience, and one that is unerringly precise.

But how does it achieve this? Well, it first incorporates various pieces of corporeal welding equipment, including masks, professional torches, and gloves, each of which have been technologically and digitally enhanced to create an optimized and more immersive user experience.

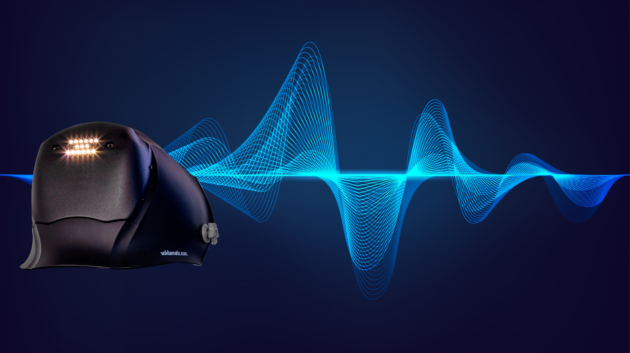

For example, the masks are fitted with remastered HD sound, which has been recorded in an actual workshop and contributes to the multisensory Soldamatic experience. This way, students can practice while hearing typical workshop sounds, enabling them to develop the requisite levels of focus and concentration.

The corporeal welding torches feature haptic technology that creates realistic vibrations during usage, while also allowing users to interact with the practice through naturally occurring body movements. As for the gloves, they’re expertly designed to replicate the weight and size of a typical welding experience, allowing users to get to grips with the practice in a completely safe and controlled environment.

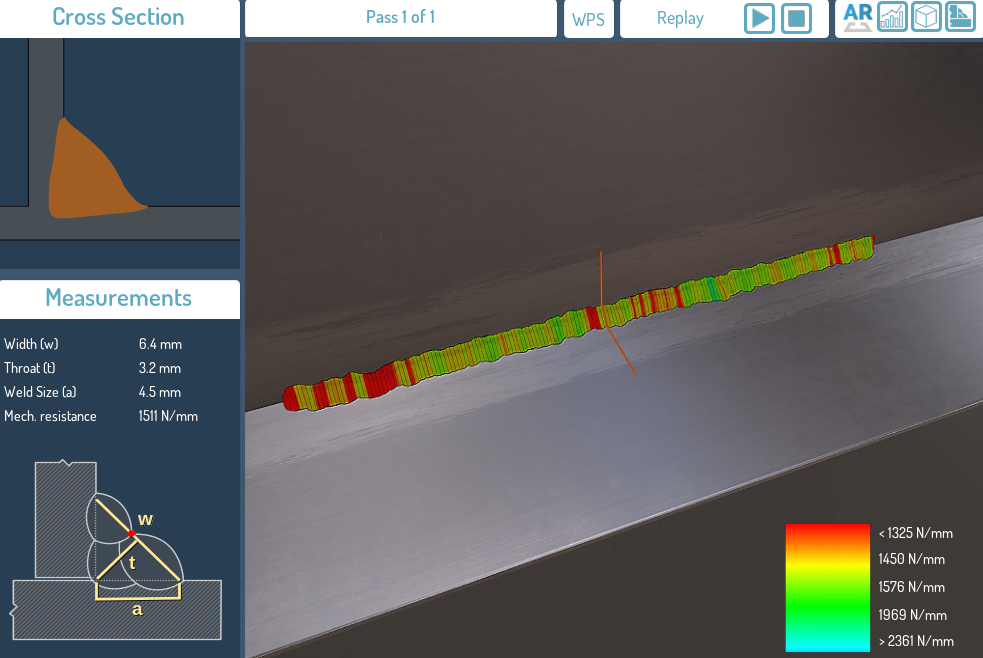

HyperReal-Sim™ is also built on the principle of calibration, which parametrizes welding simulations according to actual welding procedure specifications (WPS’s).

This allows for realistic simulations across different scenarios and welding applications, from the analysis of micrographs to taking a recording of the bath weld.

What are the Advantages of HyperReal-Sim™?

There’s no doubt that HyperReal-Sim™ underpins a completely unique and incredibly immersive training experience, and one that can teach precise and complex techniques in a completely safe and risk-free environment.

But what are the other core benefits of HyperReal-Sim™? Here are a few to keep in mind:

#1. Create the Next Generation of Welders

There remains something of a labor crisis in the welding industry, in the form of an aging and under-skilled workforce and a global shortage of workers.

The American Welding Society is predicting a shortfall of 400,000 welders by 2024, while Millennials are hardly rushing to fill these voids in the workforce.

HyperReal-Sim™ can help in this respect, as it continues to leverage cutting edge equipment and provides flexible training that can be updated in line with industry and technological trends. AR-inspired training is also considerably more appealing to younger workers, with Millennials and members of Gen Z 71% more likely to use augmented reality frequently compared to older generations.

HyperReal-Sim™ also enables students to retain knowledge at a superior rate and safely attain the attention to detail and high standards that are central to the industry, future proofing the integrity of the marketplace in the process.

#2. AR Creates the Best of Two Distinct Worlds

By incorporating corporeal environmental elements and physical welding hardware alongside cutting edge technology and parameterization, HyperReal-Sim™ is able to leverage augmented reality to create a truly optimal learning experience.

For example, the use of enhanced torches and gloves allow for safe but realistic learning, which ensuring that users can interact with even complex welding processes using completely natural body movements.

Over time, this also builds muscle memory and teaches the correct posture when welding, which translates into a demonstrable, 56% reduction in learning times and 84% fewer accidents when compared with manual trading practices.

#3. It Delivers More Certified Welders

It’s also interesting to note that HyperReal-Sim™ is associated with greater efficiency and output, delivering 34% more certified welders than traditional training methodology.

At the heart of this is the technologies calibration and accurate parameterization of various welding simulations and scenarios.

The data garnered by the software can also be used to highlight key areas for improvement and further development, creating tailored and more effective learning courses while ensuring that students are kept engaged for the duration of their course.

Both factors are crucial to creating certified welders who have the skills to work successfully in the modern marketplace, which is surely the primary goal when investing in any type of training or simulation module.

The Bottom Line

HyperReal-Sim™ is the first program of its type to successfully leverage AR and integrate this into a workable welding simulation and training model, with this delivering multiple benefits to both industry and students alike.

It also provides a direct solution to the global welding shortage, by appealing to a younger demographic of potential welders and equipping them with the skills that they need in the technological age